FAQ Topics

Acoustic Guitars

Custom Orders

Care & Maintenance

Necks

Pickups

Finish Options

Design Options

Serial Numbers & Dating

Warranty & Registration

Parts & Repair

Custom Orders

Can I order an instrument directly from Collings?

Unfortunately, we do not sell instruments directly from our shop. All custom orders must be placed through an authorized Collings dealer. Please visit our dealer page for a complete listing of dealers.

Can I provide my own wood for a guitar that I'm planning to order?

Unfortunately, we are unable to use customer supplied woods. While you may have a wonderful set of wood, we go to great lengths to source the highest quality materials for our instruments and prefer to build with our own wood. This way we can ensure that the wood is properly cut, seasoned, and structurally sound.

How long does it take to place a special order?

The lead time for new orders can vary depending on the wood combination, features, and existing backlog of orders. Most standard models can be delivered within 4-5 months. If you are considering placing a custom order, your dealer will be able to provide you with a price quote and time frame for delivery. All custom orders must be placed through an authorized Collings dealer.

Care & Maintenance

What type of polish should I use?

Any high grade, commercially available polish should be fine. There is some question about silicone and the effect it has on guitar finishes. We do not believe that silicone will cause any direct damage to our finish. However, if you ever need finish work done later, there may be trouble with adhesion over any area that has been treated with a silicone product.

How can I tell if I need to humidify my guitar?

Our guitars are built in a controlled environment with constant 49% relative humidity. In order to keep your instrument in proper playing condition and prevent cracking or other structural problems, it is very important that you maintain a similar level of humidity where you store your instrument. In many climates, it can be difficult to achieve an adequate humidity level without help from a soundhole humidifier. We strongly recommend investing in an inexpensive hygrometer to monitor the environment where you store your instrument. A hygrometer can help you gauge whether your instrument is in danger of becoming dried out or over-hydrated. We also recommend familiarizing yourself with the symptoms of a dry guitar, so you can identify potential problems before they cause any real damage. This is an extremely important topic, so please visit our Care and Maintenance page for additional information.

What type of humidifier do you recommend?

There are a wide variety of products out there that can help you keep your instrument properly humidified (see Care and Maintenance). Most of these products work in a similar fashion, but we've been especially impressed with the Oasis line of humidification products. It's also a good idea to invest in an inexpensive hygrometer to help you monitor the environment where you store the guitar. A hygrometer will help take the guess-work out of knowing when and when not to humidify.

How can I prevent my instrument from developing cracks?

The overwhelming majority of cracks (and lifting bridges) are caused by inadequate humidity. Exposing your instrument to a low humidity environment can cause the woods to contract and change shape, which can lead to cracking and a host of other problems. It's extremely important to be aware of the humidity where you store your instrument. This is an extremely important topic, so please visit our Care and Maintenance page for more information.

Setup

What type of strings do you use?

We use D'Addario phosphor bronze strings and have for many years.

For small bodied guitars (Baby, OM*, 0, 00, 000, C10), we use:

J16s - light gauge (.012, .016, .024, .032, .042, .053).

For large bodied guitars (D, CJ, DS, SJ, Archtop), we use

J17s - medium gauge (.013, .017, .026, .035, .045, .056).

*An OM should be fine with medium gauge strings. Due to the footprint of the "belly" bridge, there should be plenty of glue surface. For the Baby, C10, 00 and 000 models, we strongly recommend the use of light gauge strings. The small bridges simply do not allow enough glue surface for the increased tension of medium gauge strings.

How do I adjust my truss rod?

All of our acoustic guitar necks can be adjusted with a 5/32" ball-end allen wrench. The "ball-end" part is important, as this is needed to access the truss rod nut at an angle. Be sure to use the correct wrench to avoid stripping the truss rod nut. Please view the following diagram.

What are the factory specifications for acoustic guitar setup?

String Height (measures top of fret to bottom of string):

Bass-side string height at 12th fret: 3/32"

Treble-side string height at 12th fret: 2/32"

Relief (measures distance from top of fret to bottom of string while fretting the 1st and 15th fret):

Relief at 5th Fret: .005" (a post-it note folded in half is about .005")

We consider these measurements to be a "medium" action height. You should have some room to lower the action from these measurements, but keep in mind that an ultra-low action usually requires lighter playing or adjusted technique to prevent buzzing. Feel free to give us a call if we can be of any help.

Necks

What neck profile and bridge options are available for the acoustic guitars?

Please see the following reference chart for a summary of nut width and string spacing options.

How do the Vintage and "Vintage Now" neck profiles compare to the standard profile?

We offer three different neck options for our 14-fret guitars that vary in size and shape. The easiest way to understand the differences between our neck profiles is by looking at the saddle spacing. With wider saddle spacing, the neck gets larger as you move up towards the body. Our standard (non-vintage) neck has 2 3/16" spacing at the saddle. This neck has a modified V shape and is available with a 1 11/16", 1 23/32", or 1 3/4" nut width. The neck depth (including the fingerboard) is typically .855" at the 1st fret and .945" at the 9th fret. The fingerboard width measures 2.042" at the 9th fret.

The next size up is the profile called "Vintage Now" which has slightly wider spacing at the saddle (2 5/16") with 1 3/4" at the nut. This neck is slightly larger than our standard (non-vintage) profile, but is not quite as large as some of the chunkiest vintage Martin necks. This neck has more of a vintage feel, but is more palatable than our standard Vintage neck (see below) to a lot of players. The neck shape is slightly rounder (less V) in the lower position and moves towards a modified V shape as you go up the neck. The neck depth (including the fingerboard) is typically .845" at the 1st fret and .960" at the 9th fret. The fingerboard width measures 2.125" at the 9th fret.

The chunkiest neck option is the standard Vintage neck profile, which has 2 3/8" spacing at the saddle with 1 3/4" at the nut. This neck profile was modeled after several pre-war Martin's and is a noticeably larger neck. Like the "Vintage Now" neck, the neck shape is slightly rounder (less V) in the lower position and moves towards a modified V shape as you go up the neck. The neck depth (including the fingerboard) is typically .845" at the 1st fret and 1.020" at the 9th fret. The fingerboard width measures 2.155" at the 9th fret.

Please see the following reference chart for a summary of nut width and string spacing options. Aside from the neck and saddle spacing, there is no difference between a "vintage" and "non-vintage" model.

What type of fret wire do you use?

Our standard fretwire dimensions are as follows:

crown width: 2 mm

crown height: 1.10 mm

Tang width: 0.51 mm

Total height 2.60 mm

I would like to have a strap button installed in my guitar. What location do you recommend for the installation?

Please view the following diagram.

How is my guitar's neck attached?

Please view the following diagram.

Pickups

What type of pickups do you recommend for your acoustic guitars?

There are a number of pickup options available for acoustic guitars, and the best choice really depends on the individual player's needs and preferences. We generally recommend L.R. Baggs products and have had good results with the Anthem, Lyric, and Element pickup systems. Other popular option are the Pure Mini pickup system from K&K Sound, as well as the Matrix and Rare Earth systems from Fishman. Your dealer should be able to offer further advice in selecting the best pickup to suit your individual needs and can generally help with installation.

Finish Options

Do you offer different types of sunbursts?

Yes. We offer a few different sunburst types to suit the various body sizes and woods. We generally like the color of the edge of the burst to match the sides of the guitar. The standard sunburst for each model is determined by the wood combination and body size:

D, OM, Baby, DS, 000, 00, and 0 Series:

Sunburst guitars with mahogany back and sides will receive a 1-style sunburst as a standard. Sunburst rosewood guitars will receive a darker 2-style sunburst as a standard. We can also offer a 2-style sunburst on Mahogany guitars by request, although this option requires changing the stain color of the back and sides from the standard reddish mahogany stain to a darker walnut color. Koa guitars will receive a light amber sunburst that matches the back/sides, similar to a 1-style sunburst. The full body sunburst option is available for guitars with maple back/sides and all mahogany guitars.

CJ, SJ, and C10 Series:

These models will receive a darker pear-shaped sunburst with a more closed in upper bout. Sunburst mahogany models will receive the darker walnut stain color as a standard. The full body sunburst option is available for guitars with maple back/sides and all mahogany guitars.

Custom Sunbursts:

In a custom order situation (placed through an authorized Collings dealer), we can usually match the sunburst to a provided reference photo. While we do this on a regular basis with good results, it's important to understand that a number of variables can come into play when dealing with photos of sunbursts. Monitor color settings, camera flash, light temperature, and contrast settings can all alter the way a sunburst appears in a photo. When ordering a custom sunburst, we can generally get very close to matching color and shading, but you must be willing to accept reasonable variations to the provided reference color. Reference photos can be submitted through your dealer by email or mail for physical prints.

How does the varnish finish option compare to the standard lacquer finish?

Varnish is a softer and therefore more flexible finish material. While there are subtle tonal advantages to the varnish finish, this option is not for everyone. Unlike lacquer, the process for applying varnish is not conducive to "finish touch-ups", meaning that we cannot repair some minor imperfections such as small pinholes, bubbles, or sinks. While we've always taken pride in our high standard for fit and finish, we cannot produce varnish instruments to the level of cosmetic "perfection" as we can with our lacquer finish instruments. The varnish finish has a beautiful, rich luster, but may include very small imperfections when put under close examination.

Additionally, the softer finish is not as protective as the harder lacquer finish. The alkyd resin-based varnish finish is very slow to cure and can be relatively soft on new instruments. The finish will continue to harden as the instrument ages, but new varnish instruments can be vulnerable to scratches, dings, and imprinting. By its very nature, varnish can shrink, wrinkle, and/or dull over time and is not likely to maintain a "new" appearance as well as lacquer instruments. With that said, the varnish finish allows the instrument to vibrate more freely and can produce a more responsive instrument with a greater depth of tone.

Design Options

What is a tongue brace and why would I want to leave it out?

The tongue brace is a flat, thin brace that runs across a guitar's upper bout underneath the tongue of the fingerboard. String tension is always pulling the neck and fingerboard towards the body of an acoustic guitar and a tongue brace helps to reinforce this area to prevent the top from cracking along side of the fingerboard tongue. This cracking is only a potential problem and one that most likely wouldn't be an issue for 40 or 50 years. The tongue brace was originally developed in the late 1940's after cracking occurred on some popular pre-war instruments.

There are a few reasons why people order guitars without tongue braces or remove them:

1) Some players believe that the absence of the tongue brace allows the top to vibrate more freely, and therefore produce a subtly more open sound.

2) Some players like to try and duplicate pre-war bracing designs as much as possible.

3) Clarence White's 1935 D28 didn't have a tongue brace. Many builders offer "Clarence White-style guitars" like our CW model in which we leave out the tongue brace.

In the past 25 years that we've been building the CW model, we've never had a problem with the top cracking along the edges of the tongue. In the long run, a tongue brace is a good safeguard against tension cracks, however if you would prefer to have it left out it should not appreciably affect the structural integrity of the guitar for many years.

What is the difference between Sitka and Adirondack spruce for bracing?

Sitka spruce is the standard brace material in most of our guitars and it is both strong and responsive. Generally sitka has a less rigid structure than Adirondack which makes it more responsive to a light touch or finger-style playing techniques. Adirondack is both light and rigid which gives it a subtly quicker and clearer response, however it sometimes requires more picking effort to achieve full volume and tone. The tonal advantage of Adirondack's extra stiffness is increased headroom, the guitar will retain more tonal clarity as it is strummed harder. In either case the tonal difference of brace material will be subtle, but we offer the option to use Adirondack or sitka spruce for bracing as another way to tailor your instrument to your personal playing style and tastes.

Serial Numbers & Dating

Where can I find my instrument's serial number?

Acoustic guitar serial numbers are stamped into the mahogany neck block inside the body of the guitar. The 3-5 digit serial number can be seen by looking through the soundhole toward the neck. Serial numbers can be difficult to read in poor lighting, so a small flashlight may be helpful in accurately reading the number.

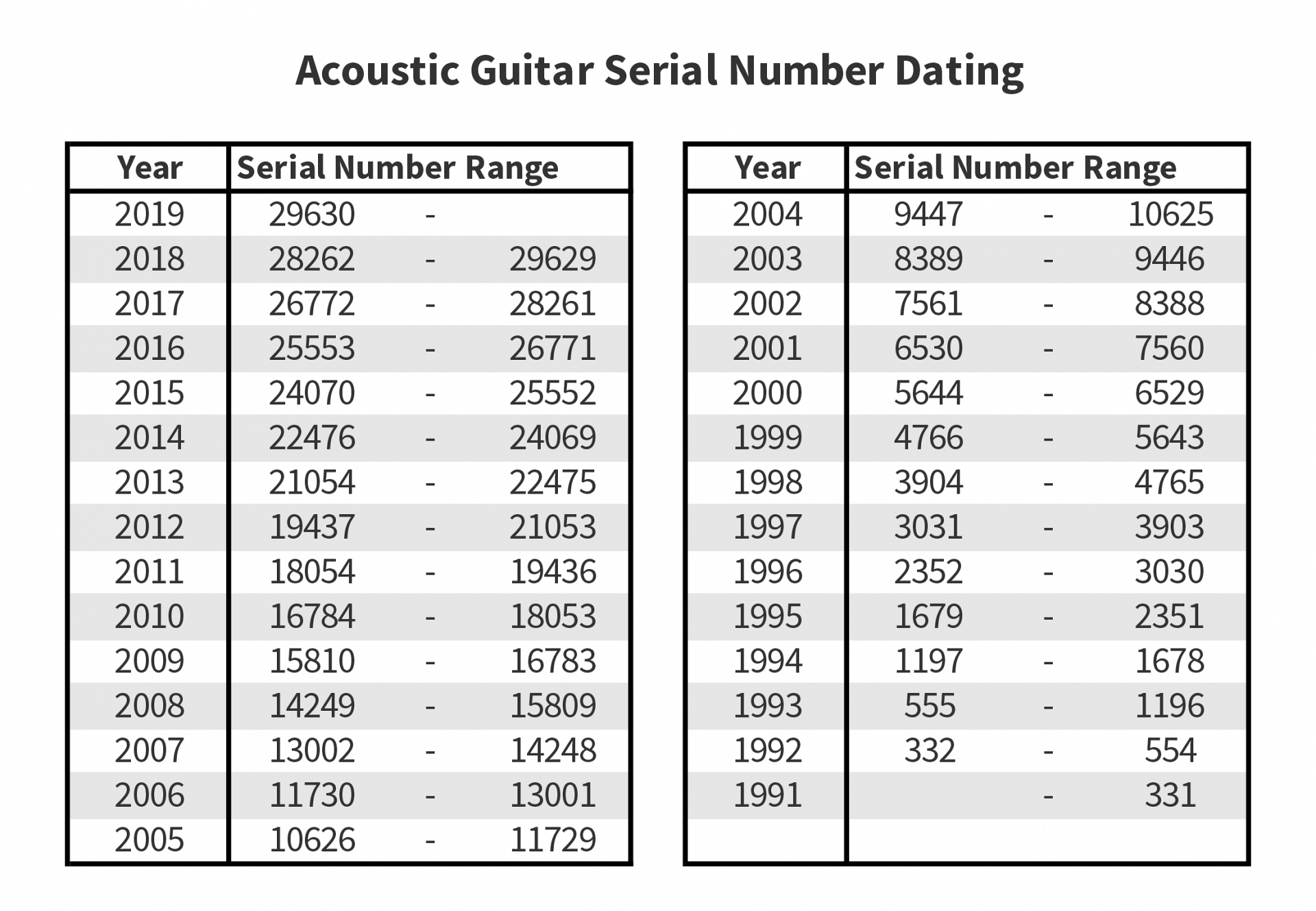

How can I determine the age of a particular guitar?

Acoustic guitars built after 1991 have a 3-5 digit serial number (stamped into the mahogany neck block) that can be used to date the instrument. You may reference the following table for a listing of serial number ranges issued into production by year.

Serial numbers are assigned at the beginning of the build process, so some guitars would have been completed and shipped in subsequent year(s). Most guitars spend 3-6 months in production, but build time can vary from instrument to instrument.

Warranty & Registration

What is covered under my instrument's warranty?

Collings instruments are warranted to be free from defects in materials and workmanship, to the original purchaser, for as long as he/she owns the instrument. This limited warranty constitutes the entire warranty of Collings with regards to its instruments. No representation or warranty by any Collings salesperson, dealer, agent, representative or employee shall be binding upon Collings Guitars, Inc. other than as expressly set forth herein.

The Collings Limited Warranty does not cover the following: wear and tear from normal use and any damage that is the result of misuse, abuse, or unauthorized modifications, damages from unauthorized or self-made repairs, improper maintenance, accidents, exposure to adverse temperature and/or humidity, and other careless action, which by its nature results in damage to the instrument or to components not manufactured by Collings.

Parts & Repair

My instrument is in need of repair. Where can I take it for service?

Your local Collings dealer is usually the best place to start. Many repair issues can be resolved by simple adjustments to the nut, saddle, or truss rod. Your dealer can most often help in this area and can also rule out the causes of common problems. Alternatively, we offer warranty repair services at our shop. Your dealer can usually assist you in packaging and shipping your guitar to our shop if needed. Please visit our repairs page for more detailed information.

I love my guitar, but would like a different neck profile. Can you build a new neck for my guitar?

It sounds relatively simple to build a new neck for a guitar, but it actually requires a great deal of time and effort to remove, build, finish, and replace a neck. We are not currently offering replacement necks, but we are happy to try to locate an instrument on order or at a dealer that matches your preferred specs if you contact our customer service team.